| Marking range |

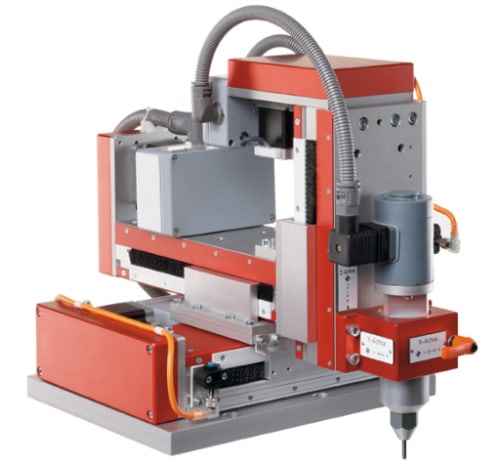

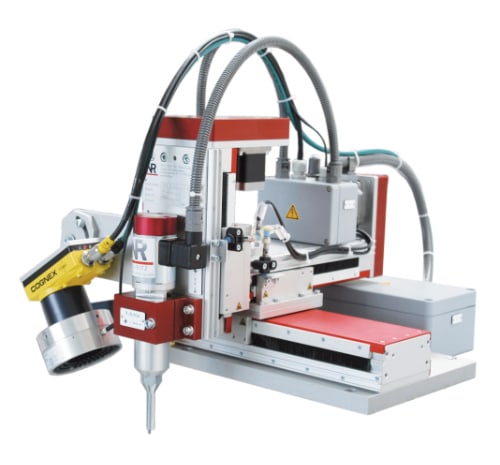

X-axis: 50 to 800 mm Y-axis: 50 to 400 mm Z-axis: 50 to 400 mm Special sizes on customer request |

| Underframe with hydraulic height adjustment (optional) | 150 mm / 300 mm |

| Speed (rapid traverse) | max. 120 mm / s |

| Resolution | 0.005 mm |

| Further data, eg for a 3-axis configuration | TSM15-5-5I (X150 Y50 Z50 mm) |

| Weight | approx. 20 kg |

| Dimensions (including protective hoses) | approx. 370 x 500 x 400 mm |

| Electrical connection | 230 V, 50 Hz / 800 VA |

| Compressed air at pneumatic Z-axis | 4-6 bar |

| Software WinCamPro included |